High Speed Automatic Tissue Napkin Paper Converting Machine Napkin Paper Folding Machine

Basic Info

| Model NO. | 180-350 |

| Function | Multi-Function |

| Tissue Type | Pull Out |

| Transport Package | Wooden Package |

| Origin | Henan |

| Production Capacity | 50 Sets/Month |

Product Description

Description

330Mm Single Color Printg 1/4 Folding Napkin Tissue Making Machine

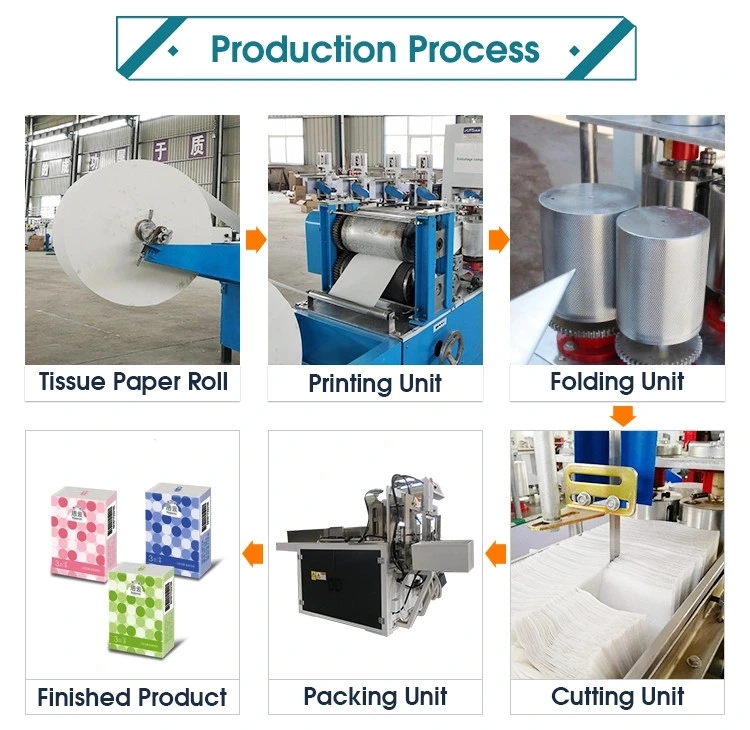

The high-speed napkin machine is used for embossing, folding, electronic counting, cutting and processing into a square napkin.

The production process is automatically embossed and folded without manual folding. The pattern of the napkin can be made according to the needs of users. Different clear and beautiful patterns.

| Machine Model | HY 180-500 |

| Finished Size(mm) | 180mm*180mm-460mm*460mm |

| Paper Size(mm) | ≤φ1300mm |

| Paper Core Inner Dia | φ75mm Standard(Other Size are Available) |

| Embossing Roller End | Cots,Wool Roll,Steel to Steel |

| Counting System | Electronic Counting |

| Power | 4-8kw |

| Dimensions | 3200mm*1000mm*1800mm |

| Weight | 1000kg-3500kg |

| Speed | 0-900sheets/minute |

| Optional Items | Automatic Paper Feeding,Synchronous Conveying and Printing |

| Use of Power | Frequency Control,Electromagnetic Speed |

Working Principle

Napkin Paper Making Machine Is Used to Making Napkin Paper by Embossing,Printing ,Folding and The Embossing and Printing Style Can Be Customized,The Printing Color Can Be 1 or 2 Color (Optioned).Variable Choices Will Be Provided to You ,We Are Confident That Our Product Will Meet All of Your Requirements.

Performance Characteristics

1. The whole machine frequency control, the unwinding adopts stepless speed regulation, and the function parameters are adjustable;

2. It can produce 1/4 or 1/6 or 1/8 fold according to requirements. Other folding methods can be specified;

3. Can be equipped with color printing device, using flexographic printing;

4. Pneumatic paper feeding device;

5. Automatic counting function;

6. Paper break automatic shutdown system

7. Fast production speed and low noise, suitable for home production.

Service

1. Pre-sales Service

- Offering comprehensive technical and business consultation services;

- Proposing the most suitable scheme and equipment for our clients;

- Designing and fabricating targeted products according to the special requirements of clients;

- Training periodically high qualified service technician.

2. After-sales Service

- Highly inspecting equipments in every working procedure, quality comes first;

- Fast & Safe Delivery;

- Assisting our clients for foundation construction of equipments;

- Dispatching engineers to install and debug equipments;

- Training the first-line operators on site;

- Regularly visit clients to solve production problems;

- Providing life-long maintenance service;

- Providing technical exchanging;