High Speed Pet Under Pad Machine with Servo Control

Basic Info

| Product Object | Adult |

| Designed Speed | 150-400pcs/min |

| Production Speed | 150-400pcs/min |

| Computer Control Panel | Computer Control Panel |

| Product Specification | Large |

| Automatic Grade | Full Automatic |

| Certification | CE |

| Condition | New |

| Transport Package | Container |

| Trademark | JWC |

| Origin | China, Jaingsu, Jinhu |

| HS Code | 84418090 |

| Production Capacity | 30 Sets |

Product Description

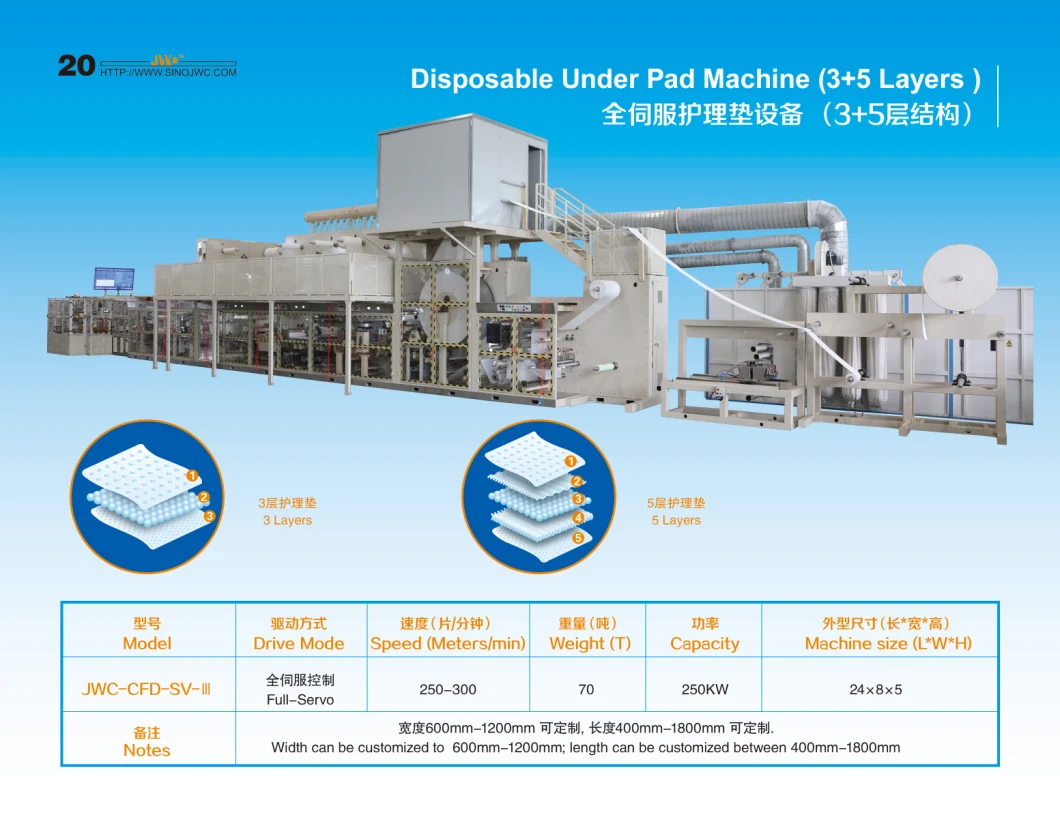

Product Parameters

| 1 | Design speed | 300meters/min |

| 2 | Working speed | 280meters/min |

| 3 | Qualified rate | ≥ 98%(exclude the wastage due to theglue applicators and materials splicing joint) |

| 4 | Efficiency | ≥ 85% |

| 5 | Installation capacity | 250KW |

| 6 | Electricity | Three phases four wires 380V/50Hz (ground wire) |

| 7 | Wire | 3×95MM2+1×25MM2+1×16MM2 |

| 8 | Lowest pressure | ≥0.6mpa , 2.6m3/min |

| 9 | Total weight | 50tons |

| 12 | Machine size | 25×8×5M(L×W×H) |

| 13 | Working space | 29×10×6M(L×W×H) |

| 14 | Machine color | Metal beach yellow+ sky blue can be changed by order |

| 16 | Containers | 3×40HQ+1×20GP |

Under pad Machine:Main Features:

- High speed. To meet the requirements of modern production, we must use high speed production line. The running speed of our Under pad machine could be 300 m/min, with qualify rate ≥97%. With such a machine you could easily make millions of products per month.

- High intelligent. The machine function includes auto unwinding, auto splicing, auto folding, auto cutting, etc. No manual during to whole process. Just put the materials on the racks and the machine will make them into final products automatically. Meanwhile, the HMI on the touchscreen will help controlling the machine with just some single taps.

- High efficiency. Running efficiency ≥85%. With good operation and machine maintaining it could higher.

Key parameters:JWC-CFD-SV Full servo under pad production lineDesign speed: 350meters/minRunning speed: 250-280 meters/min (5 layers ,treated pulp, fluff GSM 40-50/M2)Qualified rate: ≥ 98%(exclude the wastage caused by glue applicators or splicing joint)Efficiency: ≥ 85%Installation capacity: 300KW Main machine330KW including the glue machineElectricity: Three phases four wires 380V/50Hz (ground wire) Wire: 3×95MM2+1×25MM2+1×16MM2Lowest pressure: ≥0.6mpa, 2.6m3/minTotal weight: ~76 tonsMachine size: 24×8×5 M(L×W×H)Working space: 28×10×6 M(L×W×H)Products: Five layer productsMachine color: CustomizedProduct size: 5 layers pads: Width: 450-600mm adjustable, length 450-1500mm adjustable

Company ProfileAdvantages:

- Mature technology. JWC has been in hygiene products & machines industry for over 25 years. Since year 1996, we've exported hundreds of machines to 116 countries all over the world. No matter what the customers require, we are always trying our best to provide the most appropriate solutions.

- Complete and considerable service. Including: Training your staff at Purity. Co.(another company of JWC Group); on-site installing & test running; non-profitable OEM service; 24*7 remote assistance and material analyzing & trading service.

- One year guarantee time, all life-time after sale service. With in one year, all the damaged parts could be replaced free of charge (except of man-made damage or wearing parts). We've developed "individual mark" system which will give every part an unique mark. With the mark we could find the right part you need in the shortest time.