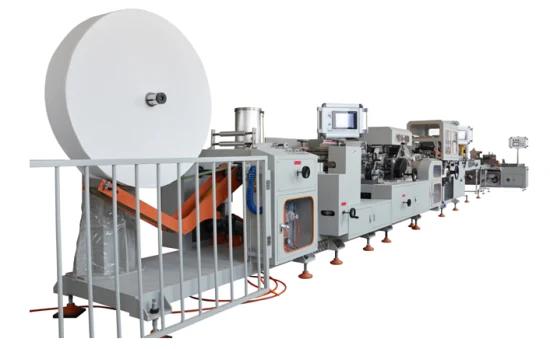

Pocket Tissue Converting Line Machinery

Welcome to IMAKO Automatic Equipment Co., Ltd!For over 5 years, IMAKO has been the automatic machinery specialist. This

Basic Info

| Model NO. | TP-H150 |

| Material Type | Solid |

| Packaging | Wooden Case |

| Packaging Material | Film |

| Stable Product Speed | 120 Pack/Min |

| Transport Package | Wooden Case |

| Specification | CE, RoHS |

| Trademark | Imako/ASF |

| Origin | China Shantou |

| HS Code | 842240000 |

| Production Capacity | 60set/ Year |

Product Description

Welcome to IMAKO Automatic Equipment !For over 5 years, IMAKO has been the automatic machinery specialist. This 5 years witnessed the fast expansion of IMAKO from the initial 11 staffs to now more than 150.We are the market leader and innovator, and will maintain this position by providing unmatched quality, exceptional service, continuous research, and aggressive new product development efforts.

We offer a broad array of premium automatic packing machine options. In addition to single facial tissue packing machine, we manufacture full automatic facial tissue bundler, full automatic handkerchief production line, and toilet roll wrapping as well as bundling machin.High Speed Single Facial Tissue Packing Machine Model: TP-H150150

Capacity and warranty

a. product guarantee speed:120packs/min

b. effective productivity≥85%

c. qualification rate≥97%

d. handkerchief quality

1. use surface is positive, few and short folds;

2. cutting side is smooth, no black and burr;

3. regular fold, derangement is 2mm, no inner fold and backslash;

4. handkerchief format tolerance is±3mm;

5. side embossing is symmetrical and clear, no delaminating.

e. wastage of parent parent paper roll, label and film≤3%

f. control system: completely self-contained, run stably.

Technical Specification

1. Handkerchief Format

A. Single handkerchief unfold size: Square: 200mm± 2 mm 210mm± 2 mm

B. Single handkerchief Fold size: Mini: 72 mm± 0.5 mm× 53.5 mm± 0.5 mm (L*W)

Standard: 105mm± 0.5 mm× 53.5 mm± 0.5 mm (L*W)

C. Side embossing is symmetrical and tolerance is 5 mm

2. Machine Size: 1610*2000*2000. Mm (L*W*H)

3. Electric power: 30.5KW

4. Bundling Unite Specification

A. Packing speed: Design speed≤ 25/, Product speed: ≤ 20/;

B. Packing size: Length: 75mm-105mm;

Thickness: 24± 2mm; Width: 50mm± 2mm;

Bundling style: : 2X3; 2X4; 2X5; 2X6;

3X3; 3X4; 3X5; 3X6.

C. Power: Supply: 380V± 38V, 50Hz± 1Hz

D. Total power: 2.5Kw

E. Main machine power: 0.25Kw

F. Main air pressure: 0.6Mpa

G. Bundling unite size and weight: 2300X1250X1450mm (L*W*H), 1000kg

5. Material requirements

A. Parent paper roll: Diameter≤ φ 1600mm, width 420mm, core diameter φ 76mm

GS 13.5~15.5G/M2(triple), 16~18G/M2(double);

B. Film: PE with thickness 0.045 mm, width 115mm, diameter ≤ φ 460 mm, core diameter φ 76mm, dark color mark (except green), size 4× 12mm, equal distance (single film length)168± 2mm;

C. Label: Width: 25± 5mm, equal distance ≥ 2 mm, color should be clear different with color mark.

6. Other requirements

A. Main power supply: 380V± 38V, 50Hz± 1Hz; 24 VDC;

B. Compressed air: Pressure≥ 0.6 Mpa, flow rate≥ 48m3/h;

C. Nagtive pressure: Pressure≥ 0.06 Mpa, flow rate≥ 480m3/h(roots vacuum pum, no need water).

| Items | Guarantee |

| Product guarantee speed | 120 packs/min |

| Qualification rate | ≥ 97 % |

| effective productivity | ≥ 85 % |

| Handkerchief quality | 1. Use surface is positive,few and short fold; 2. Cutting side is smooth, no black and burr; 3. Regular fold, derangement is≤2 mm,no inner fold and backslash; 4. Handkerchief format tolerance is ±3 mm; 5. Side embossing is symmetricaland clear, no delaminating. |

| Packing result | 1. Handkerchief tissue inside is neat and the tightness is the same. The surface is smooth, square and symmetrical ; 2. The sealing is firm and no hole. Tip triple is symmetrical and good look. Open part is no broken hole or stick with tissue. Film cann't discolorate, no pollution tissue. 3. Virtul line is in the middle, tolerance is ±2 mm,easy to open. 4. Label position is in the middle of virtul line,left-to-right tolerance is ±2 mmand up -to-down tolerance is ± 1mm. Stick is firm, no inner fold and backslash. |

| Wastage of parent paper roll, label and film | ≤3% |

| Control system | Completely self-contained, run stably |

Send to us