Toilet Paper Making Machine Line, Tissue Paper Making Machine, Sanitary Napkin Paper Making Machine, Kraft Paper Machine Kraft Paper Making Machine 5ton 8ton

Toilet Paper Making Machine Line, Tissue Paper Making Machine, Sanitary Napkin Paper Making Machine Xi yi is a China tis

Basic Info

| Customized | Customized |

| Condition | New |

| After-sales Service | 1 Year |

| Colour | White |

| Model | Model No 1880mm |

| Producing | 5ton Ton Per Day |

| Paper Wide | 1900mm |

| Output Weight | 13-40G/M2 |

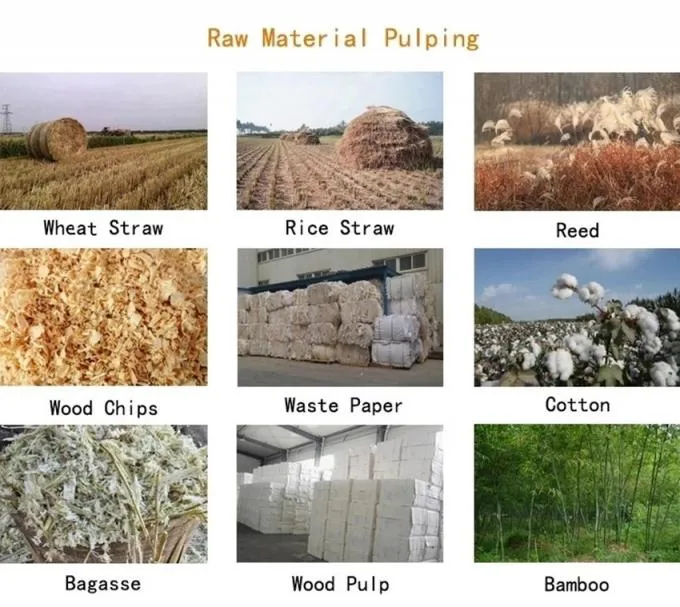

| Raw Material | Waste Paper or Rice Straw |

| Boiler Method | Using Gas |

| Transport Package | Wooden Case |

| Specification | to be customized |

| Trademark | XinYi |

| Origin | China |

| Production Capacity | 50set Per Year |

Product Description

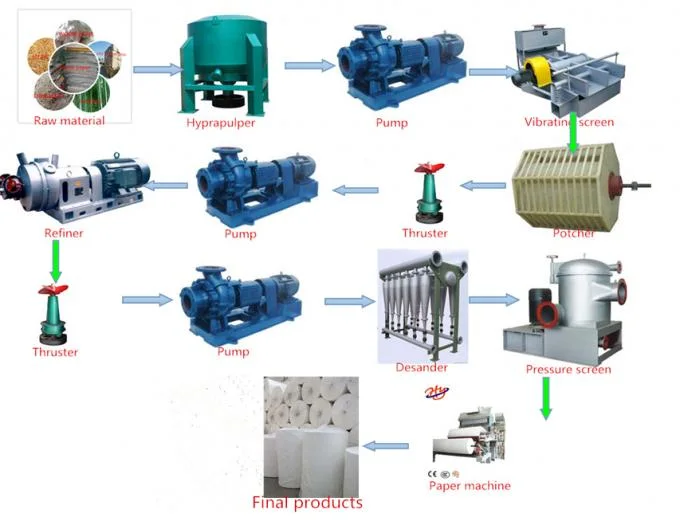

Toilet Paper Making Machine Line, Tissue Paper Making Machine, Sanitary Napkin Paper Making MachineXi yi is a China tissue paper machine manufacturer, we produced 787mm and 1092mm ,1760mm,1880mm,2100mm,3200mm small toilet paper production machine since 1980, 1880mm tissue paper manufacturing machine is a type of machine that can produce 5 to 6 ton of tissue paper per day. We welcome all clients from all over the world to order this kind of medium tissue paper machine from our factory. The 2880mm wide toilet paper machine designed and manufactured by our company can meet the requirements of the industry standard and the agreement requirements and quality standards reached by both parties. The equipment configuration of this machine can reach the predetermined production capacity, and the internal and appearance performance requirements of the paper machine are mainly considered. This machine is a complete set of well-designed, well-manufactured, advanced technology and high-quality equipment.

Here are our toilet paper making machine data:

1.cylinder section:

Ф1500mm×2350×2900mm stainless steel cylinder mould 1set

2.couch roll section:

Size of couch roll isФ450mm×2350×2900mm,material of roll body is seamless steel pipe.

Thickness is 14mm . roll surface is coated by rubber, rubber

hardness HSD 38ºC±2.

3.frame:

Frame of cylinder section is welded with shaped steel. thickness is 10mm.

4.washing device of cylinder section:

Pulp-spraying Pressure former adapt water pressing type. spray pipe DG32 stainless steel .ceramics hard wearing nozzle .

5.felt washing section:

High pressure cleaning device 2 sets

6.vacuum suction box :2set in all

7.body frame:

body frame is iron casting. material is HT200.

8.dryer cylinder :

Dryer cylinder (Φ 2500mm×2350mm×2900mm)bearing type dryer cylinder.

9.scraper of dryer cylinder:

Scraper of dryer cylinder is pneumatic, include air control chest, air cylinder.

10.touch roll:

Touch roll ( Φ 550 × 2350 × 2900),roll body(iron casting)surface rubber coating thickness is 25mm,shore hardness is 93°, pneumatic pressurizing ,include tyre, aircontrol chest but not contains air pump. equipped with 113632bearing.fluted rolls.

11. sink roll:

Φ194×2350×2900mm seamless steel pipe

12. spreader roll:

Φ230×2350×2900,rubber coating of the surface ,rubber coating thickness is 15mm,shore hardness 93±2ºC,equipped with bearing 3612.

13. exhaust hood of dryer cylinder:

Exhaust hood of the dryer can is type of respiration. include blowing fan,draft fan,radiator.

14. This machine is equipped with electromotion blanket tightening implement .pneumatic adjusting blanket implement.

15. Winding part:

sweat cylinder Φ900×2350×2900,equipped with bearing(113520 )

Picture sample and clients visiting us .

wecome to visit us or send email to us .

Send to us